Successful decarbonisation cannot be achieved without changing how products are made and accessed. Understanding your product footprints and options for decarbonisation will also be important for minimising your exposure under the Carbon Border Adjustment Mechanism. Progressing the three key steps to product decarbonisation effectively requires attention to customer and consumer needs, and lifecycle impact to result in environmental and commercial success.

These three key steps to product decarbonisation include:

1. Product Footprints

The product decarbonisation journey initially requires product carbon footprints. Understanding where in the product lifecycle greenhouse gas (GHG) impacts occur is critical for taking action to reduce those emissions. The product carbon footprint quantifies the GHG emissions associated with producing and using your product. With a lifecycle view, it considers raw material extraction, manufacturing, distribution and sale, use, end of life, and the transportation steps in between. While it’s relatively simple to complete the lifecycle assessment (LCA) needed to assess the carbon footprint of a handful of products, it may seem overwhelming to assess a portfolio of 10’s of thousands of SKUs. Fear not–while complicated, it is feasible to create actionable footprints for even very large product portfolios. Here are a few tactics:

- To optimise responsiveness to customer needs, consider beginning your portfolio footprinting effort by focusing on products that are in high demand and produced in relatively high volumes or for products customers have expressed an interest in lower product footprint options. If you are unsure which areas your customers care about, engage them to collect product-specific insights.

- Consider streamlining your process by focusing on products/services that share common lifecycle features (e.g., they contain similar materials or components).

- Take a portfolio view – For an expeditious start to footprinting a large portfolio, assess the footprint of a single product that represents a category of similar products, then scale your results to the entire category. Implementing this approach for several product categories optimises effort and allows subsequent investigations to focus on the most likely high impact product categories, lifecycle stages, and/or materials.

- Engage your suppliers for data. Using third-party databases can be effective, but engaging your suppliers provides greater accuracy. With greater accuracy, you will have a more robust understanding of how changes in procurement and/or product design could affect product footprints.

Product Footprints and Scope 3

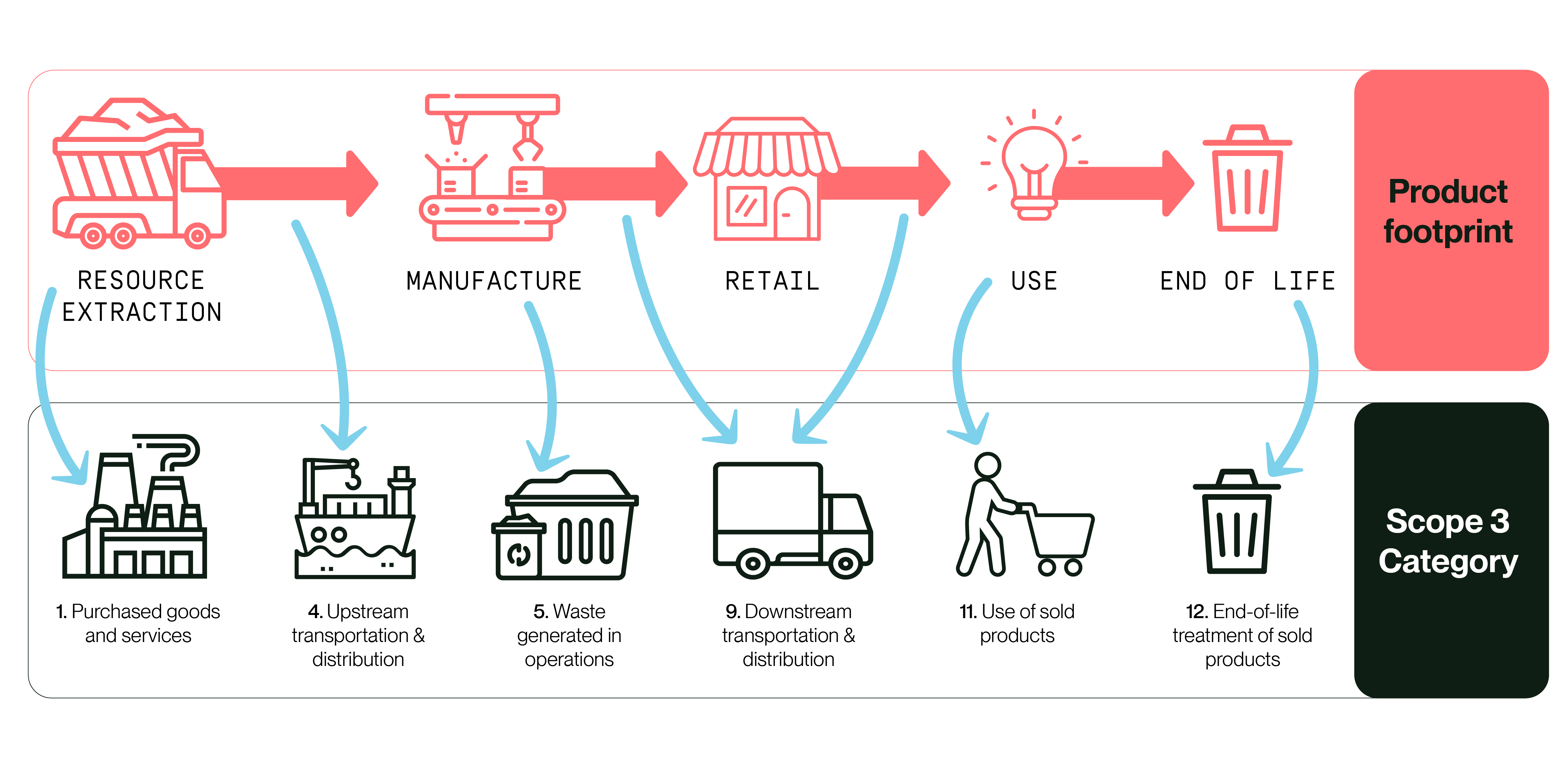

Product footprinting is useful to improving the robustness of your Scope 3 inventory as well. As shown in the figure below, the footprint for each product lifecycle stage directly informs specific Scope 3 categories. More granular product footprint calculations can be used to refine Scope 3 calculations that were based on generalised quantification methods. In the next section we’ll talk about how product footprint reductions can reduce Scope 3 emissions.

2. Direct Product Footprint Reduction

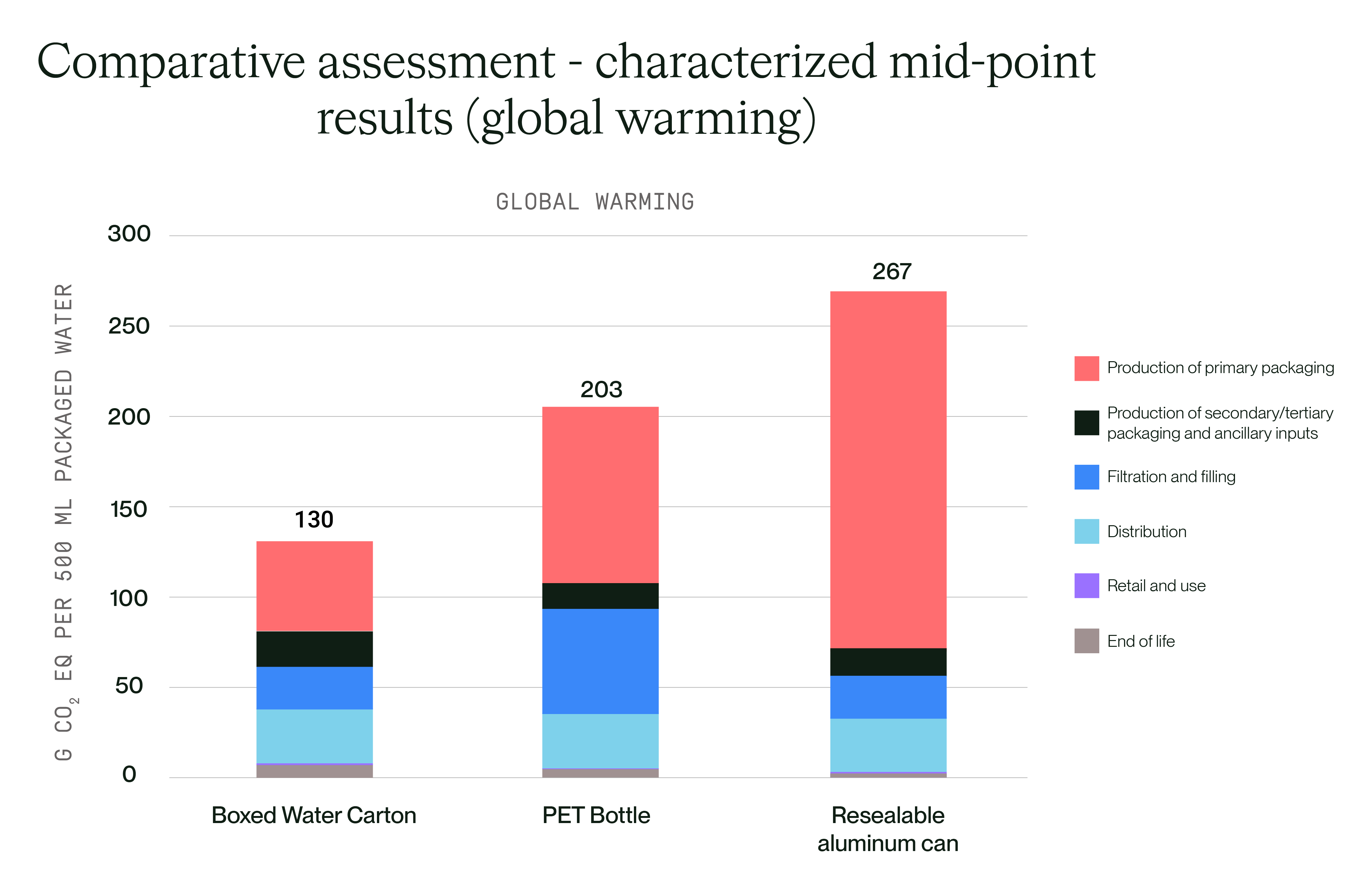

With product carbon footprints in hand, the next steps are to identify and assess the highest potential opportunities for reducing GHG impacts and to implement those best options. A well-crafted product footprint allows the user to see which materials and processes make the greatest contribution to overall impacts. For example, in Figure 2[1], we can see that the production of primary packaging contributes significantly to the product footprint for a resealable aluminum can. Opportunities for reducing the water carton product carbon footprint might be to further improve primary packaging production or product distribution efficiencies or use lower carbon fuels in either lifecycle stage. The next step would be to investigate and implement the most feasible and most effective of these options.

Reductions can be realised by substituting lower carbon input materials or feedstocks, designing products to be more efficiently manufactured, improving the energy efficiency and carbon intensity of manufacturing sites, optimising logistics systems, and designing products for more efficient use and circular end of life. A comprehensive approach to product footprint reduction is redesigning the product development process so that sustainability performance (including carbon footprint) is considered and optimised through each stage of the development process.

Improving Scope 3 and Scope 4

As noted earlier, each lifecycle stage of a product carbon footprint aligns with a Scope 3 category. Should a product manufacturer reduce their product footprint through lower carbon feedstocks, this would result in a lower Scope 3, Category 1 footprint. The magnitude of that Scope 3 reduction is related to the magnitude of the product footprint reduction and the amount of product produced. Lower carbon footprint products can also lower the purchaser’s Scope 3 footprint in cases where the product operates more energy efficiently than a competing product on the market. While these “Scope 4” or “avoided emissions” are outside of the manufacturers value chain, the manufacturer can highlight for customers the overall lower product carbon footprint of their product compared to alternatives.

3. Footprint Reduction Through Circular Revenue Models:

Product access is as important to decarbonisation as is production. Circular revenue models help to disconnect revenue generation from environmental impact through value-creation activities such as resale, re-commerce, rental, leasing, and product-as-a-service (PaaS). Specifically, circular revenue models enable an organisation to transact a product multiple times, thereby generating more revenue per item. This incremental revenue can scale over time and reduce the need to produce as many new products to achieve revenue targets. By decreasing production, the negative impacts of production can be significantly reduced. A well-designed circular revenue model helps a company deepen customer loyalty, extend revenue creation from existing products, and frequently to control its own secondary market. The process for creating a circular revenue model includes firstly identifying the model that best fits with the company’s brand and customer journey. The second step is to blueprint the model, complimenting existing assets with qualified vendors to create a high-value commercial plan. Critical at this stage is to reassess the environmental outcome of the prospective model, as poorly designed models, such as those with excessive logistics, can increase rather than decrease GHG outcomes.

Product decarbonisation is one important element in the pursuit of product sustainability. While the journey to GHG net zero is critical, one must be mindful not to cause other environmental or social degradations along the way. While assessing options to reduce the product GHG footprint, include an assessment of other environmental and social changes that might result.

Undertaking product decarbonisation in this fashion is the best path for robust high-value outcomes.

Anthesis helps you achieve your product decarbonisation goals, drawing on our deep expertise in chemicals and materials, product design, packaging, LCA, resource recovery, and circular revenue models. We support you throughout your journey, from footprinting to opportunity assessment and through to solution implementation.

We are the world’s leading purpose driven, digitally enabled, science-based activator. And always welcome inquiries and partnerships to drive positive change together.