The global business community has been talking about carbon emissions for decades. Many have set goals to reduce emissions from their operations (Scope 1) and from the energy they consume (Scope 2). For most, however, the bulk of the emissions generated by producing products or services lies in the purchased supplies and services of the value-chain (Scope 3).

Packaging, an essential part of most every product, is part of a producer’s Scope 3 emissions. Sooner or later, an accounting for emissions due to packaging and a reduction strategy will become important for any comprehensive sustainability plan.

Where do you start?

Setting a strategy always requires an assessment of the current state. For packaging, this current state is commonly referred to as a “packaging baseline.”

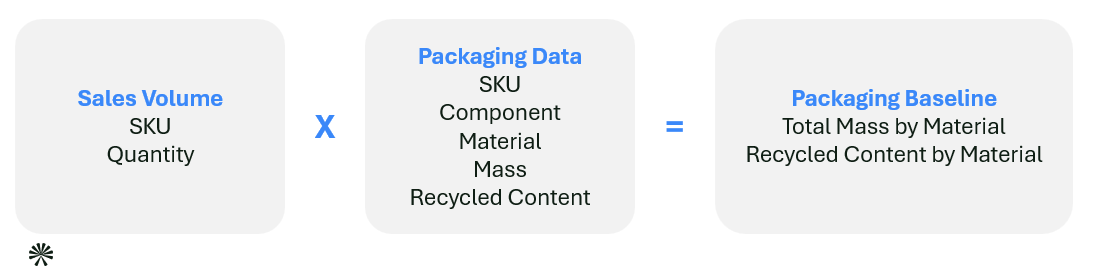

A packaging baseline provides a complete picture of the packaging required to complete a company’s annual sales results. A packaging specification database is built and matched to sales results to create a picture of packaging mass consumed by material type.

This schematic represents a simplified packaging baseline suitable for carbon emissions calculations:

For many, the challenge lies in constructing a good packaging data inventory that can be used for many different purposes related to sustainability and compliance.

Emission factors, specific to the material and the amount of recycled content contained, are applied to generate carbon emissions calculations. This is commonly called a “carbon footprint.” Emission factors can be derived from industry databases or specific supplier life-cycle assessments.

What can you do to lower the carbon footprint of your packaging?

Reductions can fall into two categories:

- Absolute – requires removing packaging from the product.

- Intensity – requires reducing emissions of packaging for each product produced.

Absolute reductions can only be achieved by removing components from the packaging. While it might seem possible, it is hard to imagine this being practical. Even pick-your-own strawberries have some packaging burdens associated with seeds, fertilisers, ground covers and the reusable container used to transport them home for enjoyment. We cannot forget that reusable containers have emissions associated with each reuse that are tied to the emissions used to produce them in the beginning.

Intensity reductions work to lower the packaging emissions for each product produced. Some of the common ways to achieve intensity reductions are:

- Removing unnecessary components

- Is that overwrap really required, or just nice to have?

- Can the product be safely palletised without a shipper box?

- Reducing Material Usage

- Is reuse of the container a feasible option?

- Can the thickness be reduced without increasing damage?

- Substituting Materials

- Can recycled content be used?

- Are suitable bio-based materials available?

A cautionary note is appropriate here: the only sure way to know if the moves that you are considering for packaging intensity reductions are viable is to perform a life-cycle assessment. A simplified assessment will compare the current packaging to the proposed options and provide a potential impact that can be weighed against other options and considerations.

How Anthesis Can Help

The Sustainable Packaging team of Anthesis is experienced in helping countless brands develop the roadmaps needed to drive goal achievement.

- Using the proprietary Anthesis Compliance Suite (ACS), our experts can help you develop a robust packaging baseline to meet all your goal reporting and compliance needs.

- Leveraging expertise in products and packaging across a wide variety of industries, Anthesis’ Sustainable Products, Packaging and Circularity team can help you set meaningful goals and strategies to attain them.

- With life-cycle analyses and experts to help you interpret them, Anthesis can help you understand which packaging change projects will get you the greatest carbon reduction impacts.

And some closing thoughts…

We have all been conditioned to think that sustainable packaging means recyclable packaging and have focused much of our activity on this particular property. Interestingly, recyclable packaging does not always have the lowest carbon footprint.

As businesses commit to comprehensive carbon reduction goals, packaging will emerge as one of those opportunities for reductions. Today, the opportunity is not well understood. You can get ahead of the wave by reaching out today.

We are the world’s leading purpose driven, digitally enabled, science-based activator. And always welcome inquiries and partnerships to drive positive change together.