Contents

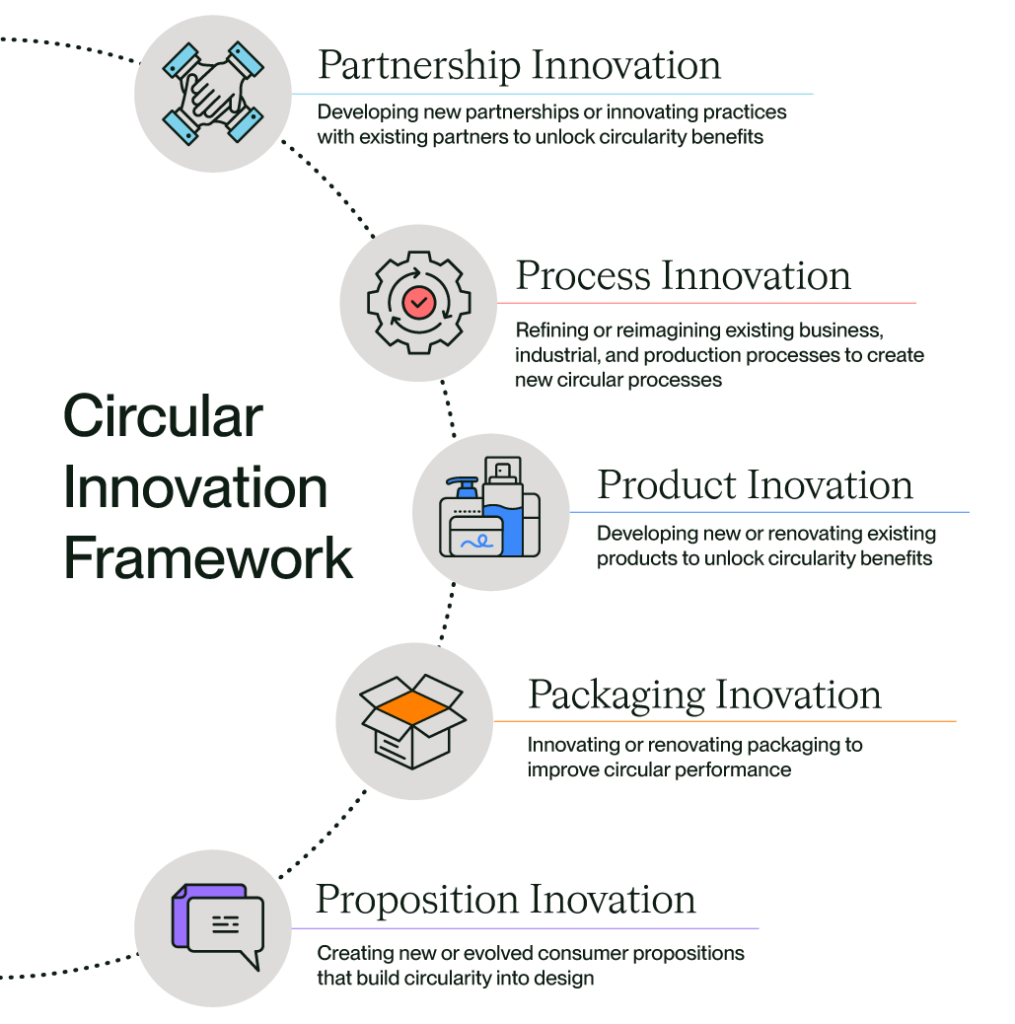

- Partnership Innovation

- Process Innovation

- Product Innovation

- Packaging Innovation

- Proposition Innovation

- Contact us

Share this article

Business leaders and investors are rapidly coming to appreciate the commercial risks and opportunities in sustainability. This means that many more organisations are designing sustainability programmes, and these programmes are becoming more ambitious.

Typically, strategies are implicitly devised and structured to inspire improvements in the sustainability of existing, linear business models.

However, the associated goals and commitments almost always imply a need to:

- Create radically more value from fewer resources

- Reduce and eliminate the environmental degradation associated with the model

In this, companies have replicated some of the central challenges facing the global economy and the planet at large:

How can we get much more, from much less?

How can we avoid wrecking the planet while we do it?

Growing numbers of our clients recognise the promise – indeed, necessity – of circular economy practices in meeting their commitments. But, while this is an area that has been vigorously theorised, researched and advocated over recent years, practically speaking, many struggle to know just how to get started.

In practice, clients find there’s a need to somehow systematise where to look for the big opportunities and the big changes they are going to need to make, as well as to identify where they might be able to align Circularity with the broader sustainability and business agenda, to deliver multiple benefits. We believe that this framework can provide a useful tool to guide innovation and maximise benefits.

We’ve seen again and again that one of the most powerful outcomes of ‘stepping up’ on circularity can be that, because it requires innovation, it drives innovation. Not ‘just’ on sustainability, but from a holistic, business perspective.

Looking across these five areas can be a practical way to identify where you can have big impacts that help to make your organisation smarter, better, and more efficient – as well as more circular and more sustainable.

Partnership Innovation

Inherent in the idea of the circular economy are new practices of cooperation and collaboration in the wider business ecosystem. We are a very long way from seeing this as the norm, but increasingly, the shared and interdependent nature of sustainability challenges is driving businesses to look differently at their existing partnerships, and to consider new kinds of cooperation that may not otherwise have existed.

For instance, many of our clients recognise that to deliver real change in their supply chain, “in the weeds” of Scope 3, they are going to need to change the way they work with suppliers. And this is not a bad thing. In fact, for many, it’s a conclusion they’ve come to for other reasons during the Covid pandemic.

In supply chains, we’ve seen very public backlash where suppliers have been left with unpaid orders. In the fashion industry, it’s estimated around $40billion dollars’ worth of stock was left sitting in factories, ordered but unpaid for by brands and retailers until the #PayUp campaign found huge resonance with consumers around the world and forced many brands to pay their debts.

Dealing in new ways that shorten supply chains, or create positive partnerships for both the business and the supplier, can help overcome these problems.

Tesco’s Sustainability-Linked Supply Chain Finance Programme

Launched in 2021, supported by Anthesis, the programme offers suppliers access to tiered financing rates linked to sustainability performance, provided by Santander. Suppliers are assessed based on the disclosure of greenhouse gas emissions, setting reduction targets, and delivering on goals, which will help address embodied carbon and contribute to circularity. That’s an example of what we can do to help supply chains where solutions exist, and access is the barrier.

However, where new solutions are needed to develop low carbon technologies or advanced recycling processes, strategic alliances or investments can help businesses gain access to solutions they will need in future but can’t yet find at scale. Unilever and Neste have done this with plastics recycling technology company Recycling Technologies, forming a strategic partnership to develop and scale the recycling technology they will need in future. Another example is how H&M is investing in new fibre-to-fibre and advanced recycling technologies through its innovation investment arm, a V.C. fund called H&M CO:LAB.

In general terms, we see that many of the sustainability challenges faced by companies across industries are too big even for the biggest to handle alone. Looking to partners, existing and new, and finding new ways to collaborate around shared aims and values, has the potential to significantly accelerate progress, at scale.

Process Innovation

Thinking differently about business processes (whether sourcing, production, logistics or many others) can often yield opportunities to enhance circularity and reduce carbon, often with greater efficiency and business value. Here, circularity is often linked to LEAN and LEAN production: the concept that by optimising the flow through production and minimising waste, a business can make the most of its resources in the most efficient way.

Businesses commonly have LEAN or operational efficiency teams doing fantastic work already to optimise business processes. However, a big frustration is that often that capability is not being harnessed to help deliver sustainability improvement – or that the sustainability gains that are being made through good, resource-efficient business practice are not being counted.

Circularity and Carbon Savings

One example of process innovation is smart pattern cutting and digital sampling in the apparel industry. Traditionally, waste in making up garments has been around 20% (sometimes as high as 40%) – that’s expensive and useful fabric waste that many in the industry are now working hard to minimise using new technologies.

And of course, finding new and beneficial uses for by-products of processes can be used as inputs into another process. We often talk about these as co-products in an industrial symbiosis model where one sector uses leftover outputs from another in a series of loops so that nothing is wasted.

Importantly, when we do this, we need to consider the chemicals we use in manufacturing processes so that they are not a barrier to future use and recycling.

Product Innovation

Circular product innovation is a huge space, full of opportunities for businesses – both new and existing – that want to access new markets, find new customers, and stay ahead of the crowd (from a customer perspective or a regulatory perspective).

There are many studies showing that consumers do want and expect more sustainable products – and expect brands to put in the hard yards for them so they don’t have to go looking far for sustainable product options (a 2021 YouGov poll showed around 50-60% of consumers are willing to pay more for more sustainable products).

Likewise, regulatory expectations – around chemicals, with REACH, or around extended producer responsibility (EPR) are increasing. Across most industries, the bar is rising, with increasing use of sustainable product standards, sustainability claims and collaborative industry initiatives to drive collective improvement.

From a carbon perspective, how consumers use, care for, and dispose of products is a very important, and very hard to influence, aspect of Scope 3 emissions. Enhancing product sustainability, especially across a variety of metrics, is complex. There are sometimes difficult trade-offs to be made (between, say carbon and circularity – or between sustainability and input materials cost).

Green Design Tools

At Anthesis we have bespoke and customisable Green Design tools that can help businesses design more sustainable products that they can feel confident in, and which address circularity and carbon along with other key sustainability and business factors. For example, we worked with a leading global IT company to develop a circularity tool to support their circularity transition by allowing product managers to make lifecycle decisions informed by circularity.

Packaging Innovation

Packaging has rightly received enormous attention over recent years. A spark for many consumers was David Attenborough’s Blue Planet: seeing swathes of plastic pollution in our oceans being swallowed by turtles and birds and learning how they decay into microfibres which damage our health.

Extended Producer Responsibility

Since then, we’ve seen moves from regulators in many countries to follow through on consumer concerns by adding to the existing regulation around packaging Extended Producer Responsibility (EPR). Globally, 170 nations have pledged to “significantly reduce” the use of plastics by 2030. In the EU the plastics packaging levy, and in the UK the Plastics Tax due for implementation in force in April 2022, have created strong market drivers.

As a result of these factors, the move toward more circular, recycled content and recyclable packaging has been swift and ubiquitous across many sectors. Our Packaging team have worked with an enormous range of supermarkets, food and beverage companies, and other FMCG businesses to help them address this challenge.

To innovate in this space, you must be able to consider several impacts simultaneously: Circularity and carbon are two of these. We often work with clients to help them visualise the impact of their packaging on circularity and carbon so that they can make choices that align with their sustainability targets.

This is now standard practice in some sectors – like food and beverage – but in others, such as fashion, taking a multi-metric approach to packaging is relatively new. The bulk of the focus has understandably been on products.

Whatever the starting point, we see the key to driving true innovation through this kind of approach is not to just aim for the “least worst” option but to innovate to make a positive impact.

To begin with, that may mean making transitional changes, like developing a home refill option to reduce their packaging impact. Or it may be that where a solution doesn’t exist, you need to create one. At Anthesis, through a joint venture with design agency 1HQ, we have developed a fully integrated sustainable packaging service called Sustainable Packaging, that combines the ‘science’ of sustainability with the ‘art’ of great creative packaging design to deliver new, market-ready solutions from these historically separate disciplines.

Proposition Innovation

The last, and most revolutionary of the innovation types is proposition innovation. New business models, ways of getting products to customers, and ways of using or owning or leasing or renting products have really been seen as a whole new market for investment. When circular business models were first introduced as a concept around a decade ago, they were thought of as quite risky – would consumers actually want to hire bikes or rent clothes or other items? So far, many such models have met with great success.

For example, the 2021 Thredup report estimates the fashion resale market will grow 11 times faster than broader clothing retail, reaching a value of $77B by 2025. New, circular business models are focused on re-imagining product or service systems in new ways that generate maximum value whilst reducing sustainability impacts via leasing, “product-as-a-service”, sharing models, repair-and-retain, and other approaches.

As markets shift, particularly following the Covid-19 crisis, consumer expectations and behaviours are changing, and value chain dynamics are shifting, opening up a space for business model innovation. Many sectors have seen a switch toward Direct-to-Consumer and online sales, with implications for repeat sales, customer relationship building and so on. These trends provide an environment that is ripe for trying some of these new business models. Many brands, large and small, are dipping their toes in the water.

In the apparel sector, it seems like everyone is getting in on the act with many major brands trialling circular business models in some way. For example, Selfridges “Resell” second-hand shop in-store and online, and Ralph Lauren launched a rental offering in 2020.

Meanwhile, the “sharing economy” can provide an opportunity to intensify the utilisation of resources. Car sharing services, like Zipcar provide all the benefits of having a car when you need one, without the burdens of ownership and theoretically could reduce the number of cars on the road.

Right to Repair

Another key area of innovation is repair. The Right to Repair movement has become a hugely influential force across Europe and the US and beyond. And central to that is the idea that we should stop “built in obsolescence” and make it easier for people to repair the things they buy. This has influenced regulation right across Europe. The objective of these rules is to make appliances last longer, and reduce hugely harmful electrical waste, which is coupled with increases in energy efficiency.

The circular economy can inspire us to look at ‘old’ things in completely new ways – whether an old top in the back of a wardrobe or a well-worn industrial process. Often, knowing where to look is all it really takes to get started, because when you do, you find opportunities everywhere.

Here, we’ve shared a few lenses we use at Anthesis to systematise our opportunity spotting. As our clients become more ambitious, we are seeing a greater focus and urgency around Circular Innovation. We are collectively discovering not only how essential circular practices are for the realisation of ambitious sustainability goals but also how exciting they can be commercially in pursuit of sustainable performance.

We are the world’s leading purpose driven, digitally enabled, science-based activator. And always welcome inquiries and partnerships to drive positive change together.