Contents

- Challenges of Recycling Textiles

- California's SB 707

- The EPR Trend in Other Jurisdictions

- Preparing for SB 707

- Contact Us

Share this article

California’s SB 707 introduces the first extended producer responsibility (EPR) framework for textiles in the US, requiring producers to manage the recycling and reuse of their products to address the growing textile waste problem. The law mandates the formation of Producer Responsibility Organizations (PROs) to handle collection, sorting, and recycling, with full implementation expected by 2030. Companies are encouraged to prepare for compliance by assessing their environmental impact and developing sustainable practices.

Textile waste is a huge problem for a few reasons. Textile waste, coming largely from discarded apparel, has increased by 400% globally in the last 20 years. The production of new apparel requires intense resource use from raw materials including fossil fuels, water, land, and chemicals. Fast fashion, or inexpensive clothing driven by rapidly changing trends produced in large volumes, is a major contributor to the textile waste problem. The infrastructure for collecting, processing, reselling, repairing, and recycling textiles is massively lacking in the United States in particular. According to the EPA, only about 15% of textiles were recycled in 2018.

Challenges of Recycling Textiles

There are numerous challenges preventing optimum management of textiles at end of life. Namely:

- The collection of used textiles is not convenient for many Americans because they are not typically collected curbside. Drop off or take-back bins in retail stores or recycling centers are the main avenue for textile collection and often require consumers to make an extra trip.

- Sorting is still largely manual. People are needed to inspect apparel for condition, fiber content, and “re-sellability”. Although this provides employment opportunities, this manual sortation process is slow and requires a trained eye.

- The technology which enables true or closed-loop circularity, or textiles being recycled back into textiles, is nascent in the US. Any mixed fiber apparel – most commonly polyester and cotton – makes recycling challenging from a material and economic standpoint. Most “recycling” happening in the US is actually downcycling, where apparel is shredded to be reused for insulation or rags and is unable to be re-captured and recycled again. This only extends the inevitability that the material will ultimately end up in landfill.

The State of California recently passed SB 707 (or “the bill”) which aims to channel textile producer funding to tackle the various challenges in textile recycling, including collection, infrastructure, and the development of necessary technology at scale. Moreover, the law seeks to encourage producers to create apparel designed for circularity.

California’s SB 707 Aims to Enhance Textile Recycling via the EPR Approach

In essence, SB 707 requires apparel and textile “producers” in California to form a producer responsibility organization (PRO) to enhance the recycling and reuse of textiles, thus introducing the nation’s first extended producer responsibility (EPR) framework in the industry. The EPR will legally hold producers financially responsible for end-of-life management of the products they place in a certain market.

According to the bill, a “producer” includes:

- Manufacturers, or the exclusive licensee (if the manufacturer is not in the state),

- Product importers (if the manufacturer and exclusive licensee are not in the state),

- Product distributor/retailers (if the manufacturer, exclusive licensee, and product importer are not in the state), and

- Wholesalers (if none of the above are in the state).

It should be noted that SB 707 excludes secondhand sellers and sellers with less than one million dollars ($1,000,000) in annual aggregate global turnover.

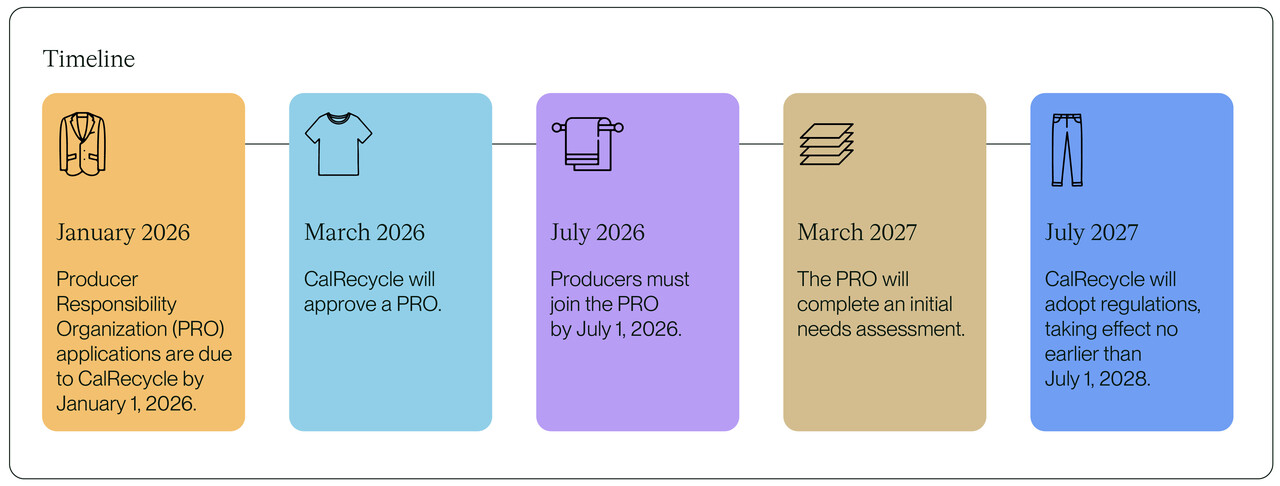

SB 707 also requires apparel and textile article producers to form and join a PRO. PROs must submit applications to the Department of Resources Recycling and Recovery (“the department”) before January 1, 2026, describing how they will comply with the bill. All producers of covered products must join the department-approved PRO by July 1, 2026. Although the specific implementation details are not available, a PRO shall undertake the following obligations under SB 707:

- Recycle Plan: The PRO must submit a comprehensive plan for the collection, transportation, repair, sorting, recycling, and safe management of apparel and textile articles in the state for the department’s approval. The PRO is required to review and evaluate the approved plan at least every five years. Additionally, the bill requires online marketplaces to notify the department and the PRO of any third-party sellers whose sales of apparel or textile articles exceeded $1,000,000 in the previous year. They must provide all necessary information and inform these sellers about the relevant laws governing the PRO plan.

- Annual Report: The PRO must submit an annual report to the department. All reports and records provided to the department must be submitted under penalty of perjury.

- Fee Payment: The PRO must pay a fee to the department to implement and enforce the Bill. All money received from PROs will be deposited into the Textile Stewardship Recovery Fund in the State Treasury.

The State will adopt regulations to implement SB 707 by July 1, 2028, with full rollout by July 1, 2030. Producers or the PRO must submit and annually update a list of brands of covered products that each producer sells, distributes, imports, or offers for sale in the state.

The department will post a list of compliant producers on its website. Non-compliance will result in civil penalties (up to $50,000 per day), which will be deposited into the Textile Stewardship Recovery Penalty Account in the State Treasury.

The EPR Trend Adopted by Other Jurisdictions

Although SB 707 is the first EPR program in the apparel and textile industry in the country, EPR is already well developed in the U.S. for items like electronics, batteries, mattresses, and paint, and has recently been passed for packaging in 5 states. EPR for textiles was formed in France in 2008 and in the Netherlands in 2023. In 2023, the European Union proposed an update to their Waste Framework Directive which would harmonize textile EPR across the region and require fashion brands to pay fees to fund textile waste collection and treatment costs. Producer fees will be based on the environmental performance of textile products, known as eco-modulation, which is intended to incentivize preferred materials and business models. The final text is expected in the legislative sessions in 2025.

How to Prepare for SB 707 Compliance

Although the program will take a few years to be fully implemented, regulated companies can proactively prepare for legislation by answering a few questions:

- Does my company fit California’s definition of a producer?

- Do we fully understand the environmental and social impacts of our product assortment?

- Do we want to be actively involved in shaping the requirements of the regulation to position ourselves as a leader?

Anthesis’ services are well positioned to support companies with California SB 707 compliance readiness.

Baseline Your Products

This service supports clients in understanding their products’ full impacts – Anthesis assists in collecting and analyzing data on product materials, identifying any data gaps, and making informed assumptions. We conduct an assessment on your material and analyze the supply chain and current material usage, enabling companies to establish realistic and achievable reduction goals.

Set specific, measurable, achievable, relevant, and time-bound (SMART) goals for reducing material usage or transitioning to more sustainable materials.

Report and Communicate

Our experts continuously monitor emerging regulations and assess their potential impact on businesses. We develop proactive strategies to address anticipated compliance requirements. Anthesis experts help clients create tailored reporting frameworks that align with SB 707 and other relevant regulations, ensuring transparency and accountability.

Action Plan Development and Implementation

Anthesis works closely with client teams to develop comprehensive action plans addressing the specific challenges and opportunities associated with textile recycling and reuse. Anthesis provides ongoing support and guidance throughout the implementation process, ensuring that companies meet or exceed SB 707 requirements.

By leveraging Anthesis’s expertise, you can effectively navigate the complexities of SB 707 and position your business as a leader in sustainable textile practices.

We are the world’s leading purpose driven, digitally enabled, science-based activator. And always welcome inquiries and partnerships to drive positive change together.