Contents

Share this article

In case you missed it, it is now 2024 and one year closer to extended producer responsibility (EPR) for packaging in the United States. But that’s not all. Extended producer responsibility laws are evolving in Canada and there are major changes coming in the European Union.

If you sell a product that is in a package, as most are, please take a moment and read this update. Under EPR legislation, producers are defined broadly as the entity that places the packaging in the market which includes brands and importers.

What follows is Part 4 – Getting Prepared of a four-part series on EPR. If you have missed the discussion of the legislative happenings in first three parts, you can go back to them here PART 1 – United States, PART 2 – Canada and Part 3 – European Union.

PART 4 – Getting Prepared

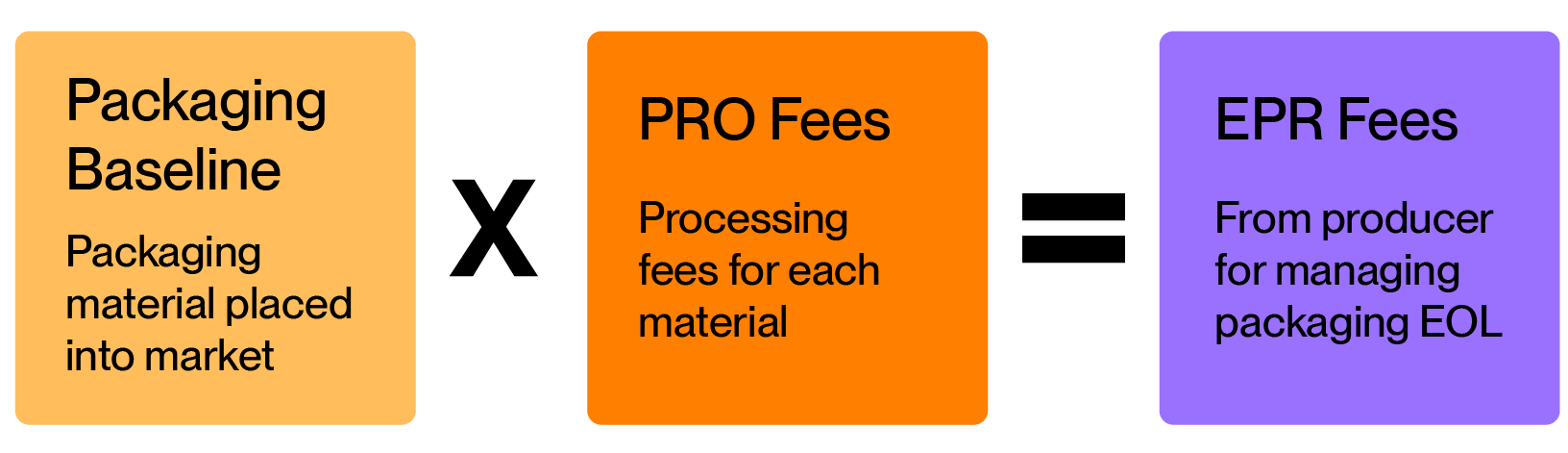

The intent of EPR is to ensure that producers take responsibility for managing the end of life of packaging placed in the market and encourage ecodesign principles. Under the legislation, fees are assessed based on the material weight and, in some cases, the packaging format. It is also important to know the source of the material to take advantage of available eco-modulation fee reductions.

Preparing for EPR involves a lot of data gathering and analysis. Better data can lead to lower fees and provide insights into strategies for lower fees in future years.

Step 1 – The Packaging Baseline

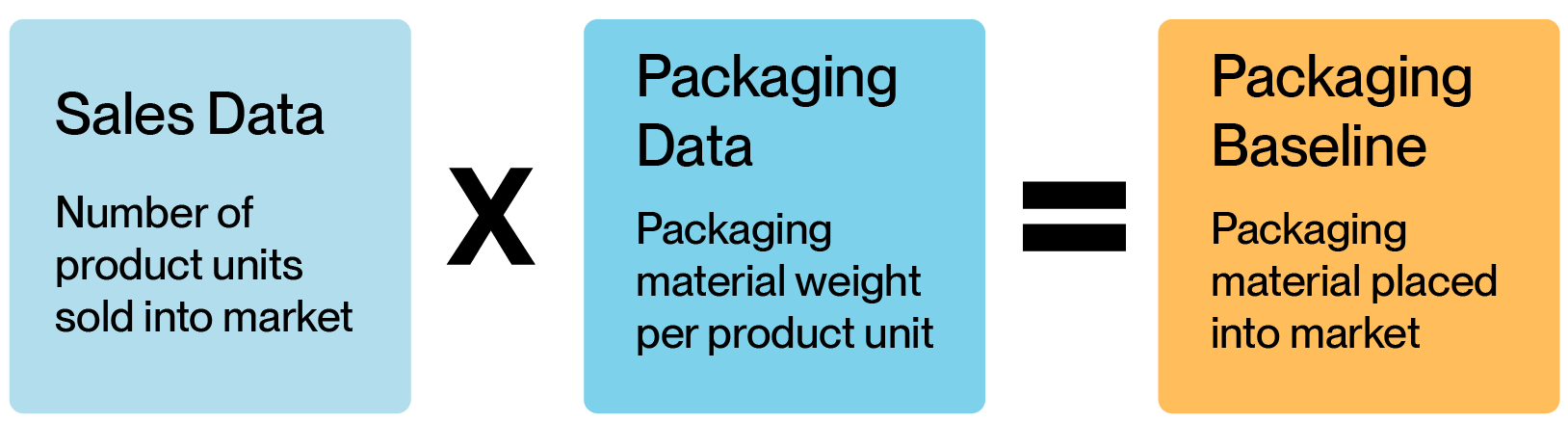

When completed, a packaging baseline provides a link between sales into a market and the packaging materials that were delivered into that market. Most companies can easily provide item-based sales data for a market. The challenge comes in determining the packaging materials used to support those sales.

Packaging data is the traditional hurdle. These are the key questions to answer:

- What are the primary, secondary, and tertiary packaging items used for each selling unit?

- What materials are used in each packaging item?

- Are there any problematic materials or items?

- Do the materials contain any recycled content?

- Were the materials sustainably sourced?

For selling units that are insourced, a bill of materials and a survey of packaging suppliers should be able to answer the key questions. When units are outsourced and packaging is included as part of the item, answering the key questions involves a detailed survey of suppliers that can consume valuable hours and distract from more strategic initiatives.

Anthesis utilises tested processes and compliance systems to streamline the supplier engagement survey process and deliver high participation rates. Proprietary uplift methods are employed to complete the dataset. All steps are well documented to ensure easy validation and replication.

Step 2 – Applying the Fees

EPR programs vary in their objectives and their fees. In most cases, the EPR program fees are collected and managed by a Producer Responsibility Organization (PRO) that was established by producers for the purpose of managing packaging waste at end of life. Most programs allow for multiple PROs to compete and deliver the best value to producers.

Legislation sets requirements for PROs to achieve certain goals (waste reduction, recycling, etc.) but usually does not set fees because the intent is to allow the PRO to efficiently deliver on the goals. This means that understanding the fee for a specific material can be a complicated task. Just look at the 37 page CITEO decision tree.

EPR fees are paid on a frequency set by the PRO. Accurate disclosures require an update of the baseline and an update of the PRO fees.

Anthesis handles the EPR reporting requirements for many multi-national corporations. The regulations, reporting requirements and the ways of most of the PROs have been studied and are routinely updated. This way, Anthesis can deliver accurate fee reports for any EPR program.

It is worth noting that the same methodology can be useful in determining the additional tax obligations for UK, Spain, and soon to see in Germany and Italy. With an accurate baseline, strategies can be developed to minimise tax obligations in future years.

Recap

- EPR compliance is a two-part process.

- A good packaging baseline provides the total packaging materials placed in an individual market. It is a data intensive task that can be complicated when outsourced units are involved.

- Accurate EPR fees require a detailed understanding of the PRO fee structure. These vary in attribute and amount, even in the same market.

- When considering packaging EPR compliance, is this something that you want to teach yourself or learn from a trusted teacher?

We are the world’s leading purpose driven, digitally enabled, science-based activator and always welcome inquiries and partnerships to drive positive change together.